Ferrite Magnets Factory: Powering the Green Energy Revolution

The global shift toward renewable energy demands materials that combine reliability, affordability, and environmental stewardship. At the heart of this transition lies the Ferrite Magnets Factory, where innovation meets sustainability to drive advancements in wind turbines, solar systems, and electric vehicle technologies. As industries seek alternatives to rare-earth-dependent solutions, ferrite magnets are emerging as a cornerstone for clean energy infrastructure, offering unmatched cost-efficiency and resilience in high-stress environments.

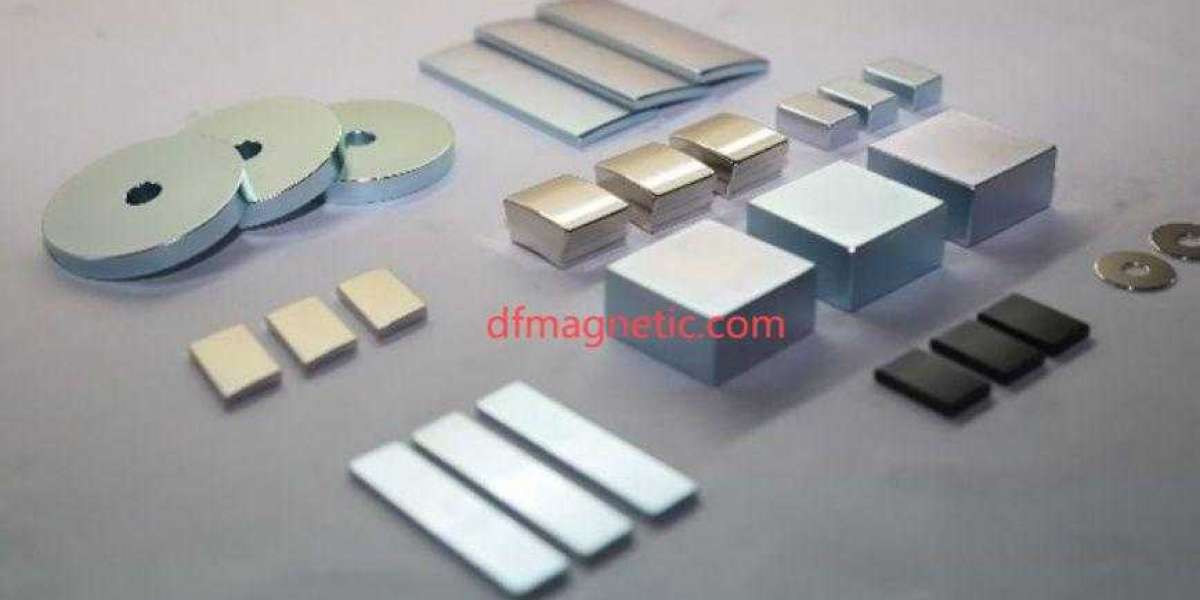

Ferrite magnets play a pivotal role in renewable energy systems. In wind turbines, they enable efficient power generation by stabilizing electromagnetic fields in generators, ensuring consistent energy output even under fluctuating wind conditions. Solar installations leverage their durability in inverters and tracking systems, where resistance to corrosion and thermal stress extends equipment lifespans. For electric vehicles, these magnets are integral to battery management systems and auxiliary motors, balancing performance with lightweight design. Their versatility stems from a unique combination of chemical stability and ease of customization, allowing factories to tailor shapes and magnetic properties to diverse green energy applications.

Enhancing magnetic performance while maintaining ecological integrity remains a key focus. Advanced manufacturing techniques, such as precision sintering and hybrid composite designs, are optimizing flux density and coercivity. Innovations in material engineering—like integrating nanostructured ferrites—are further improving thermal stability, critical for high-temperature environments in solar farms and EV drivetrains. Factories are also adopting closed-loop production systems, recycling scrap materials to minimize waste and reduce reliance on raw mineral extraction. These efforts align with global standards for sustainability without compromising the magnets' role in energy conversion efficiency.

The economic and environmental advantages of ferrite magnets are reshaping supply chains. Unlike rare-earth alternatives, their production avoids geopolitical dependencies and reduces carbon footprints. This positions Ferrite Magnets Factory initiatives as catalysts for scalable, low-cost green energy solutions, particularly in developing regions where affordability dictates adoption rates. Collaborative RD projects, such as those exploring bio-based binders and smart magnetization protocols, are paving the way for next-generation magnets that self-monitor wear or adapt to dynamic operational demands.

Looking ahead, the integration of ferrite magnets into smart grids and AI-driven energy systems promises unprecedented synergy. By embedding these materials into IoT-enabled devices, factories can support real-time energy optimization and predictive maintenance, further accelerating the transition to net-zero economies. As industries prioritize circularity and innovation, ferrite magnets stand poised to redefine what’s possible in clean technology—proving that sustainability and high performance are not mutually exclusive.

dfmagnetic.com